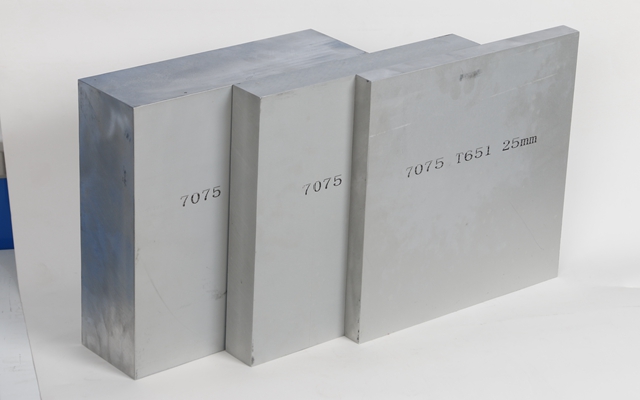

7Series

7075 aluminum plateCommon status: T6, t651

Conventional thickness: 2-250mm

Conventional width: 1000-1500mm

Conventional length: 2000-3000mm

Product application: high strength and high hardness aviation structural parts, cavities, shoe molds, molds, mobile phone shells, golf heads, etc.

Introduction: 7075 aluminum plate has high strength, far better than mild steel. Compact structure, strong corrosion resistance, best for aviation and marine plates. General corrosion resistance, good mechanical properties and anodic reaction. Fine grains make the deep drilling performance better, and the wear resistance of the tool is enhanced.

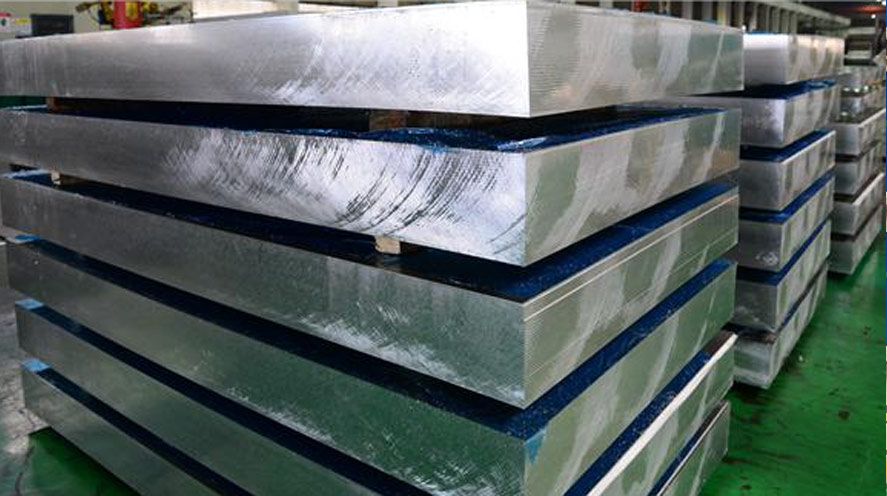

7050 aluminum plate

Common status: t651

Conventional thickness: 2-250mm

Conventional width: 1000-1500mm

Conventional length: 2000-3000mm

Product application: high strength aviation structural parts, fixtures, golf ball joints, molds, mechanical equipment, etc.

Introduction: the main alloy element of 7050 aluminum plate is zinc, which is a high-strength heat treatable alloy with extremely high strength and resistance to spalling corrosion and stress corrosion cracking.

7A09 aluminum plate

Common status: T6, t651

Conventional thickness: 2-250mm

Conventional width: 1000-1500mm

Conventional length: 2000-3000mm

Product application: beauty instrument, notebook shell, mold, high-strength parts, etc.

Introduction: 7A09 aluminum plate is super hard aluminum. It has good plasticity after solution treatment, and the effect of heat treatment is particularly good.

7A04 aluminum plate

Common status: T6, t651

Conventional thickness: 2-250mm

Conventional width: 1000-1500mm

Conventional length: 2000-3000mm

Application fields: mold, high-strength parts, chemical industry, etc.

Introduction: 7A04 aluminum plate is an Al Zn mg Cu ultra-high strength aluminum alloy, also known as superhard aluminum. It is the most commonly used superhard aluminum. It is quite mature among superhard aluminum and is an alloy that has been used for a long time and widely. The effect of heat treatment is good.